| | My L67 swap from LesabreT.com |  |

|

+2569GSColorado joshuadalegrimes denim L67GAMSE93 rivparadise gmann3001 AA pbrktrt LARRY70GS ghpcnm charlieRobinson bigdave deekster_caddy BMD stan robotennis61 RoughNecks17 flyineagle96 albertj RidzRiv Hometown Hero turtleman Karma DEMonte1997 Z-type 29 posters |

|

| Author | Message |

|---|

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 5:36 pm Sat Apr 14, 2012 5:36 pm | |

| *drools all over the place* If you don't post any more pictures I won't send you all the 'stuff' I said I was going to send you  . | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 5:57 pm Sat Apr 14, 2012 5:57 pm | |

| ... hrm... I've got a drink in-hand, its after 6... do I do a writeup? or just play Minecraft?

... ah why not... (uploading 38 pics...) _________________  | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 7:29 pm Sat Apr 14, 2012 7:29 pm | |

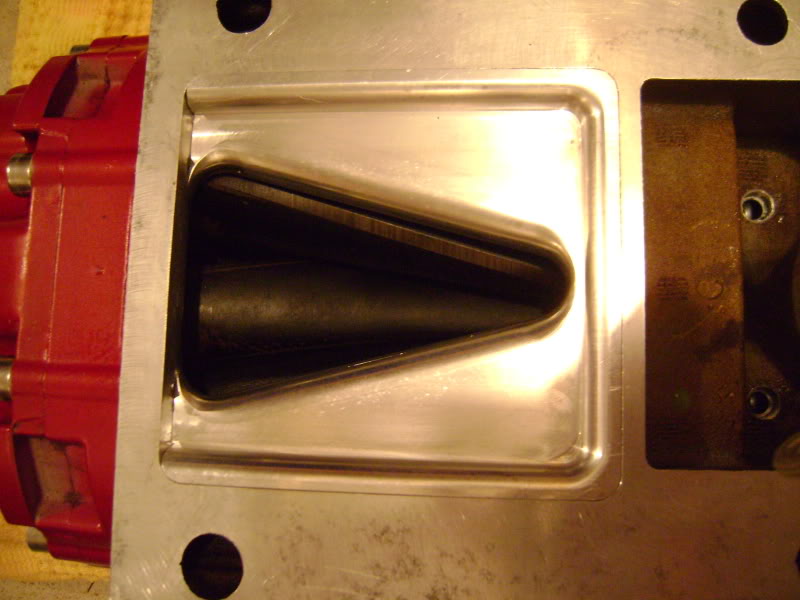

| Righto! Its now time for the hand porting part of the program. Usually I rough things in using a carbide burr dremel bit:  The spots we need to be working on are the corners of the outlet triangle where I can work the shape in by hand:  I start by knocking down the edge:  And then blending in the rounded shape:  I slowly work my way around to the other corners:  Once the rough edges are knocked off I move to a rock drum bit:  The same work is done on the top of the outlet triangle as well:  More blending work:     Then a flap sander at 80 grit:  Then 120:  240:  1000:  This outlet is done!  Moving to the inlet, I start by gently using the carbide bit clean away the crap:  Then 80 grit:  120:  And 240 to finish:   Next is to push out the needle bearings from the casing. The most common method of this is by threading in Zerk grease nipples into the air relief holes and pumping in grease behind them.  First the hold needs to be drilled to the tap-drill size. For anyone new to tapping, this is the diameter of a threaded hole at its tightest. So if you took calipers to a bolt, its the smallest DIA. You have to be careful to not nick the bearing, but make the hole as deep as possible.  I have two flat bottom taps for this. One is a normal one, the other has been cut back so that I can tap a full size hole that is not very deep. (Taps are tapered.)  Nipples installed:  And the old bearings fired out:  Next is bath time. All the chips, grease, and crap needs to be washed out of the casing. Leaving these clean holes for new bearings to be installed:  Sorry Z-type, a bit of paint came off when cleaning. It had some galvinic corosion under it. You will need to touch up the blower a bit.  For pressing in new bearings you will need a press. Most people do this carefully to get the bearing pushed in about one US dime depth. This is two Canadian dimes deep. The first SC that I did the bearings on, I measured the stock depth before removing them, and made this fine tool so its perfect every time:  Brand new bearings:  They come pre-greased:  And in they go:  Woo hoo!  Now the other bits go back on:     Next I have some stainless steel bolts and other hardware to go on and the PCV intercept to make. That will be next weekend. Got to love a perfect angled blower outlet:  FIN:  _________________  | |

|

| |

Hometown Hero

Junkie

Name : Klix

Age : 46

Location : Barrhead, Alberta Canada

Joined : 2009-11-18

Post Count : 807

Merit : 16

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 7:35 pm Sat Apr 14, 2012 7:35 pm | |

| | |

|

| |

robotennis61

Guru

Name : robotennis

Age : 63

Location : las vegas

Joined : 2007-12-17

Post Count : 5562

Merit : 143

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 7:54 pm Sat Apr 14, 2012 7:54 pm | |

| | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 8:45 pm Sat Apr 14, 2012 8:45 pm | |

| sure. Its optimizing the blower for use with smaller SC pulleys. The outlet is opened a bit to move the CFM efficiency range more in check for the speed that the blower is spun at vs. stock. Also Eaton themselves say that a proper closing of the silencer holes improves efficiency and reduces heat. Which moves us to the next HP gain. The m62 makes boat loads of heat. ANY reduction that you can come up with is new HP.. The slightly opened outlet shape, the new shape of the outlet, and the inlet porting... all go to make the air-stream cooler. Which in turn improves HP. Like normal porting of heads and inlet manifolds, its taking a mass produced factory cast item and optimizing it for your current use. Too bad this is likely my last m62 eh?  _________________  | |

|

| |

RidzRiv

Addict

Name : Greg

Age : 31

Location : Wisconsin

Joined : 2011-02-07

Post Count : 590

Merit : 17

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 9:52 pm Sat Apr 14, 2012 9:52 pm | |

| | |

|

| |

gmann3001

Fanatic

Name : Glenn W. Peck

Age : 50

Location : Orland Park, IL.

Joined : 2011-11-16

Post Count : 389

Merit : 9

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sat Apr 14, 2012 10:26 pm Sat Apr 14, 2012 10:26 pm | |

| Sweet!  | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sun Apr 15, 2012 10:32 pm Sun Apr 15, 2012 10:32 pm | |

| Wow man that's AMAZING work...I can't wait to see this thing in person! The only thing that is really disappointing is that you simply cannot see this piece of art once it's installed   . Oh, and no worries on the paint. I didn't expect it to survive the machining process and all the handling. I can fix that in no time! No problem at all  . Your 'payment' will be on the way in a few days! | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed Apr 18, 2012 10:36 pm Wed Apr 18, 2012 10:36 pm | |

| Alright, time for a crap-ton more pictures! Did a bit of work to the Lesabre in the last few days, none of it L67 related, but oh well! I have this thread already open  . Me and dad tackled the rear struts. They've been slowly fading over the past few years and they finally bit it before this past Winter, so it was time to replace them. Instead of replacing with KYB's, like the KYB's I have on the front, I wanted something more for the rear. I took a page from my old Riviera once more and installed air shocks. This isn't really a write-up, just more of an opportunity to take up space on the internet with pictures and give you all something to look at  . Neither of us had really done anything like this kind of set up (I've replaced air shocks before, but not struts) so we just attacked it.  Two bolts on top to hold the mount in, and two spindle bolts on the bottom.  Dad wrenching on the bottom bolts. See the big silver bar on the floor? Breaker bar. Made from an old trampoline frame  .  One out.  After some struggling and a broken impact extension later, both are out!  Kind of a lack of pictures this time, but we were both tired and busy figuring out exactly what we were doing. Long story short, we had to install and remove the first shock 3 times because I kept assembling the mount in the wrong order lol...like i said, long story. We got the other side installed in a flash and quit for the night.  This morning, I had a few errands to run, so I went to NAPA (hate that place, by the way) and picked up a bigger supercharger tensioner pulley. Stock on the left is 3", this replacement is 3.25". This is simply to pick up some of the slack of the belt from the smaller supercharger pulley I'll have, and to help prevent belt slip.   So I know what you're thinking..."Air shocks? But you don't have a compressor!" Taking yet another page from my Riviera - when my Riviera's compressor died, I replaced it with a manual fill valve with new air lines. That way I could add or remove pressure and ride height/handling as I pleased. Did the same thing on the Lesabre! I decided to hide the fill valve inside the trunk. To run the lines, I had to remove the tail light assembly.  I made a hole to the right of the trunk latch thing on the inside edge of the trunk. This is normally hidden by carpet.  Ta da!  This is where the tail light assembly is - this is right above the license plate.  So that T valve stays there, and I started running the air lines. First thing, connect the line to the nipple thing on the shock.  I ended up lucky enough to be able to run the lines nowhere near the exhaust so there's no chance of them melting or anything. Anywhere the line touched a rough or sharp edge, I ran wire loom around it. So, once those were run, I added the threaded compression fitting and an o-ring to attach to the T valve.  Attached both the lines to the T...   Filled the system with 50 PSI, put the wheels back on, and set it on the ground. 50 PSI is probably a bit much for ride height, so after I took this picture I ended up bleeding out the pressure down to 30 PSI. Once the shocks wear in and i get an alignment, I'll probably need to add pressure.  That's about it for now. Once the supercharger is on and everything is working correctly, the rear needs an alignment BADLY and the fuel filter changed. I didn't have the proper tools to replace the fuel filter so Ill let the guy who does the alignment do it  . | |

|

| |

rivparadise

Fanatic

Name : Samuel

Age : 52

Location : Niagara Co.

Joined : 2007-06-10

Post Count : 381

Merit : 11

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sun Apr 22, 2012 4:55 am Sun Apr 22, 2012 4:55 am | |

| | |

|

| |

AA

Administrator

Name : Aaron

Age : 47

Location : C-bus, Ohio

Joined : 2007-01-13

Post Count : 18452

Merit : 252

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sun Apr 22, 2012 9:35 am Sun Apr 22, 2012 9:35 am | |

| Nice job! You'll probably notice the ride height will settle when you take it out for the first drive. I found 40-50 works well. I installed the same kit on my Riv, but mounted the fill valve under the rear bumper. Makes adjusting a snap! _________________ '05 GTO 6.0L • 6-spd • 95k miles • 0-60: 4.8s • 16.9 avg MPG • Nelson Ledges Lap: 1:26'95 Celica GT 2.2L • 5-spd • 165k miles • 0-60: yes'98 SC Riviera • 281k miles • 298 HP/370 TQ • 0-60: 5.79s • ET: 13.97 @ 99.28 • 4087 lb • 20.1 avg MPG • Nelson Ledges Lap: 1:30

3.4" pulley • AL104 plugs • 180º t-stat • FWI w/K&N • 1.9:1 rockers • OR pushrods • LS6 valve springs • SLP headers • ZZP fuel rails

KYB GR2 struts • MaxAir shocks • Addco sway bars • UMI bushings • GM STB • Enkei 18" EV5s w/ Dunlop DZ101s • F-body calipers

EBC bluestuff/Hawk HP plus • SS lines • Brembo slotted discs • DHP tuned • Aeroforce • Hidden Hitch^^^ SOLD ^^^  '70 Ninety-Eight Holiday Coupe 455cid • 116k miles '70 Ninety-Eight Holiday Coupe 455cid • 116k miles^^^ SOLD ^^^  | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Sun Apr 22, 2012 10:06 pm Sun Apr 22, 2012 10:06 pm | |

| That's about what i figured Aaron...I vaugely remember the setup on my Riviera being the same way. I kept it at 30 for a good while, then as I drove it the shocks wore in and I kept it around 50 until the car was taken apart. I considered putting the valve on the outside somewhere but I didn't really want it exposed too much or want anyone to see it. I do my best to keep things stock appearing  . I can't wait to try them out though - it should handle a lot better than it ever did. Should be able to drive the car in 2 or 3 weeks! I know Karma is hard at work putting the finishing touches on the supercharger  . | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Mon Apr 23, 2012 8:20 pm Mon Apr 23, 2012 8:20 pm | |

| Ok, so last bunch. First we have the new stainless steel hardware: Snout:  Fuel rail and bits:   And I dunno if the shoulder is to big on these or not Andrew since I didn't have my spare TB at the shop, but I'll send em anyway.  Now, this part of the show is making a PCV intercept. Here is the first version I made, this is still running on my engine:   And goes in place of the stock PCV cover.  Basically this takes a line off the PCV valve and shunts it away to a catch-can/oil separator and then sends it back to the proper stock location. Its plug and play so you can go back to stock at any time. To start making the new version, we start with a bit of Delrin in the lathe:  Then turn out a little nub that's the same DIA as the nub on the PCV valve:  And done with a little hose barb:  This sits just above the nub end of the PCV valve when its bolted down. The connection is made by a small bit of hose. The spring assembly goes around the whole issue. Next is making the hole for the PCV exit to get out. This is done to a specific depth so the top is flawless unlike the prototype one where I had to plug it.  And done:  Next we are done with the lathe, so I just use a cut-off bar:  And off:    Next it gets mounted into the mill to square it off. This is where it will end up cleaner looking than the first one made:  Various turning around for each side. Only the first two sides were done with the end of the mill, the other two were run lengthwise.  And done:  Next the holes were put in and counter-sunk. Also a radius was put along the top edges. No pic of this process, but involves working from center of the part and running a circle function in the digital readout that finds the location of holes a certain radius from center. Bolted on:  Next the horiz holes were drilled to match out with inlet and outlet. You can see the return hole with relief space milled for air flow around the bits inside.:  Inlet and outlet holes are tapped 1/8 NPT:  Here is the whole arrangement under the prototype. Andrew, you can use smaller wall joining vacuum tube than I did. Just cut it a little small, slide it on the nub, add the spring, and push the whole assembly onto the PCV valve. Test fit without the spring first. Use a thin layer of rtv between the surfaces. Follow the directions of just tightening till the RTV oozes, wait 20 min, and then give teh screws another 1/4 turn. Be careful as Delrin can dent. It only needs to be snug. If you have any questions or its not clear, fire me a message.  And on the SC. No barbs are threaded in in this pic. They go left and right, and orientation can be turned around whichever way you want. The outlet side is marked with a small scratch:  Finished SC ready to ship:  _________________  | |

|

| |

stan

Expert

Joined : 2007-07-01

Post Count : 2558

Merit : 12

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Tue Apr 24, 2012 12:35 am Tue Apr 24, 2012 12:35 am | |

| PERFECT......Andrew !-how you people do it?.,.... | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Tue Apr 24, 2012 10:55 pm Tue Apr 24, 2012 10:55 pm | |

| Wow! i think I changed my mind about the new bolts - they look awesome! I'm sure they look even better in person too!

Excellent EXCELLENT work, my friend. Maybe I'm over-excited, but this is one of the coolest things I've ever been a part of! I've said it a dozen times before, but I can't thank you enough!

To everyone else, installation pictures and vids coming in a week or two! | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Mon Apr 30, 2012 9:28 pm Mon Apr 30, 2012 9:28 pm | |

| Got a present today, from Karma Customs:  Woohoo!! I'm psyched to get this thing running! I have to get supercharger oil for it, then it'll be ready to install. Probably doing that in the morning, then Dad wants to help put it on tomorrow evening lol. Won't be driving it, but we will fire it up and check everything. Some pics: Probably the last time we'll see this thing out in the open. It's a beautiful thing, and a serious piece of engineering.  Comparison - stock M62 on the right, ported M62 on the left.  Reeeeeeeeeeally nice angles and edges as illustrated by Andrew in his previous post earlier in the month.   Stay tuned, hopefully construction concludes tomorrow. | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Tue May 01, 2012 2:03 pm Tue May 01, 2012 2:03 pm | |

| Lemme know how/if those TB bolts I sent work. I wasn't sure if the sholders on them were too long or not.

.. How was the packing condition when it arrived? I tried to pack it as bulletproof as possible. _________________  | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Tue May 01, 2012 10:53 pm Tue May 01, 2012 10:53 pm | |

| Andrew- the throttle body bolts didn't work out too well, and didn't look quite right, so i nixed them. Thanks though! I appreciate! And the package arrived great...no issues with it, nothing seemed damaged or out of place. Alright guys, everything got back together, but there's a problem. Rocker noises GALORE. The car started right up though, has great vacuum, no visual or aural problems besides what sounds like the rockers. This video here is the first startup after re-assembly. It's hard to hear the noises exactly, but the sound that sounds like a lot of static-y air is what sounds like every rocker/pushrod on the engine.  When I installed the rockers I noticed that there was a bit of back and forth play on some of them even when torque down, like whenever both valves would be closed on a certain cylinder. The pushrods would have a bit of play. After cranking the engine a few times when I first installed them, it seemed like they tightened up some but not all of them, and not consistently. What concerns me is the Yella Terra mounting plate...it doesnt have guides for the pushrods to be right on center with the rockers. I ran the car for two minutes, twice, and the noise never quieted down. Has this happened to anyone before? Could my pushrods be too short somehow? I didn't think that was a factor with the '94-'95 engines... EDIT: Here is a video of someone else's 3800, doing exactly what I experienced when I installed them. https://www.youtube.com/watch?v=2MyfPHWNyno | |

|

| |

robotennis61

Guru

Name : robotennis

Age : 63

Location : las vegas

Joined : 2007-12-17

Post Count : 5562

Merit : 143

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Tue May 01, 2012 11:13 pm Tue May 01, 2012 11:13 pm | |

| | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed May 02, 2012 12:16 am Wed May 02, 2012 12:16 am | |

| Yeah, they should all be right tight. A collapsed lifter could give them that movement and noise. Quickest way to check that for you might be to swap on the stock rockers, if the noise is still there you know a lifter is collapsed. If not, well you know to dink around with the YT rockers some more.

Did you make sure that the pedestals all fit properly into the guide plates? The tolerances aren't great on the YT guide plate and I found I had to swap the pedestals around a bunch to have them sitting right seated. Some pedestals fit too tight, others looser. Make sure they are all right flush. I'd check that out first. Also be sure the flat bits on the rocker barrels are up. They can rotate all the way around. ... also you put the guild plates the right way around right? You should be able to read Yella Terra right side up and facing you on each side.

(I also just checked the part number on yours vs mine, just in case Intense sent you the S2 ones. But you are all good in that regard.) _________________  | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed May 02, 2012 12:25 am Wed May 02, 2012 12:25 am | |

| I came across two cases on the PontiacBonnevilleClub.com forum that were just like this, neither with conclusions so far.

I think it has something to do with the lifters but on ALL 12 rockers? In person it's easier to hear, but it sounds like all 12 pushrods are making noise against the rockers. I just think since the engine has been sitting for so long (4 months) the lifters might not have pumped up yet. But anyway, yes all the pedestals eventually fit into one hole or another, after messing with them. The flat parts are all facing upward.

I'm going to take the front off tomorrow and see if there's anything obvious going on, and maybe swap on the old rockers. Any other advice Karma? I'm going to be hugely disappointed if I can't use these things. | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed May 02, 2012 9:31 am Wed May 02, 2012 9:31 am | |

| The swap to the old ones would be the surefire way to rule in or out the new rockers as the issue. The same noise with the old ones would point directly to the lifters.

Other thing you can try is run it with the VCs off and be sure that you are getting proper oiling form each pushrod, and have proper rocker movement. That will also help locate if the noise is right at each rocker or deeper.

There should be no reason you can't use the new rockers. You just need to find out whats up. _________________  | |

|

| |

albertj

Master

Name :

Location : Finger Lakes of New York State

Joined : 2007-05-31

Post Count : 8685

Merit : 181

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed May 02, 2012 12:52 pm Wed May 02, 2012 12:52 pm | |

| - Karma wrote:

- The swap to the old ones would be the surefire way to rule in or out the new rockers as the issue. The same noise with the old ones would point directly to the lifters.

Other thing you can try is run it with the VCs off and be sure that you are getting proper oiling form each pushrod, and have proper rocker movement. That will also help locate if the noise is right at each rocker or deeper.

There should be no reason you can't use the new rockers. You just need to find out whats up. I dimly recall having to shim the camshaft mounts or some darn thing to get rockers to set right without clacking like maracas... but it was LONG ago and far away. Please consider that you may need to fab shims (for the mounts)? maybe? | |

|

| |

Z-type

Aficionado

Name : Andrew Zamiska

Age : 37

Location : Cecil, PA - 25 miles south of Pittsburgh

Joined : 2009-06-29

Post Count : 1429

Merit : 63

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  Wed May 02, 2012 1:17 pm Wed May 02, 2012 1:17 pm | |

| Well friends, I swapped the old rockers back on (only took me an hour, woohoo!) and there's zero noise whatsoever now. Before I took the Yella Terras off, though, I checked for play and torque. There was a very minute amount of play on some of them (I assume ones with valves that were closed for the moment) and torque didnt change. Still 25-26 ftlbs. I don't get it. The car starts and idles like the champ it's always been right now with the old rockers. And yes, I used the Yella Terra bolts. No noise coming from the lifters that I can decipher, so I would assume they're all good for now. Pushrods must be the problem. Albert - I wonder if that would apply as much to my Series I as it does to the Series II? Do you mean the rocker mounts perhaps? If anything they would need shaved down a hair. maybe I misunderstood  . Thoughts? | |

|

| |

Sponsored content

|  Subject: Re: My L67 swap from LesabreT.com Subject: Re: My L67 swap from LesabreT.com  | |

| |

|

| |

| | My L67 swap from LesabreT.com |  |

|