Contributed by Jack the R (Nov '05)

For tensioner write-ups, see links:

Accessory: https://rivperformance.editboard.com/t7519p15-write-up-replacing-accessory-belt-tensioner

Supercharger: https://rivperformance.editboard.com/t2887p75-write-up-replacing-supercharger-belt-tensioner Replacing Belts and Tensioner Pulleys on the 95-99 Buick Riviera Supercharged The moral of this repair is "be prepared." With these instructions, and the needed tools and parts at hand, replacing the

belts and tensioner pulleys will only take a few hours and be minimally frustrating.

Replacing the

belts and tensioner pulleys on the supercharged Riviera is considerably more involved than the same job on normally aspirated cars. It will take time and patience to accomplish, but need not be extraordinarily challenging.

The majority of the difficulty I experienced came from not knowing what tools would be needed and being unfamiliar with the car and the replacement process. Carefully read through this write up, and keep a printed copy at hand during the repair process, and you should be able to proceed with a minimum of difficulty.

Tools Needed: millimeter sockets (15, 18 mm)

millimeter deep sockets (13, 15, 18 mm)

millimeter wrenches (15 mm)

torx sockets (T50)

external torx sockets (E8, E10)

various socket wrenches/breaker bars,* and adaptors

Riviera jack and floor jack

scrap 2X4, hammer, nails, saw

*several times I found a need for a 3/8" drive breaker bar with an extra long handle (like on a 1/2" drive breaker bar), as the tight confines between the frame rail and various engine components made it impossible to use a 1/2" drive breaker bar with a 3/8" adaptor.

Parts Needed:

warning - these parts worked on my 97 (except as noted). If you have another year, check to see what parts are right for your car.Belts

warning - these parts worked on my 97 (except as noted). If you have another year, check to see what parts are right for your car.Belts -

Accessory Drive

6K938 (ACDelco#)

K060938 (Gates#)

Supercharger *

6K721 (ACDelco#)

K060721 (Gates#)

*note - This is supposed to be the correct belt for 96-99 years, but didn't work on my 97. Here's the ACDelco/Gates belt compared to my old SC belt and a 72.5" Gatorback belt -

My advice is to go with the 72.5" Gatorback belt.

Tensioner Pulleys -

Gates # 38015

Gates #38006

Gates #38009

7505118

#12564510

GR.1.062 _____ I had to get the lower SC idler pulley from a dealer.

These are the #'s I found on the box.

The Process: Make an engine support

Depending on your floor jack, you may need to make a support for the engine (don't be alarmed, but this repair involves removing a motor mount).

WARNING! It is not recommended to support the engine by the oil pan gasket. It can/will cause it to leak later on. See this post for ideas https://rivperformance.editboard.com/t725p165-write-up-replacing-belts-and-pulleys#134330

WARNING! It is not recommended to support the engine by the oil pan gasket. It can/will cause it to leak later on. See this post for ideas https://rivperformance.editboard.com/t725p165-write-up-replacing-belts-and-pulleys#134330 I carved the top of my engine support to fit between these three bolts on the oil pan.

This is what you'll be doing (but don't do it yet).

Replace 3 of the 4 Tensioner Pulleys Get yourself off to a flying start by replacing the 3 easy tensioner pulleys.

*WARNING* - All three of these pulleys use a left-hand thread. Loosen them by turning them clockwise, and tighten them by turning them counter-clockwise. This is the opposite of a normal right-handed thread! *DOUBLE DOUBLE WARNING* GM gets tricky on the 4th tensioner pulley and reverts to a normal right-handed thread! You're several steps away from removing the 4th pulley, but when you do get to it, don't be fooled! I'll remind you again later.

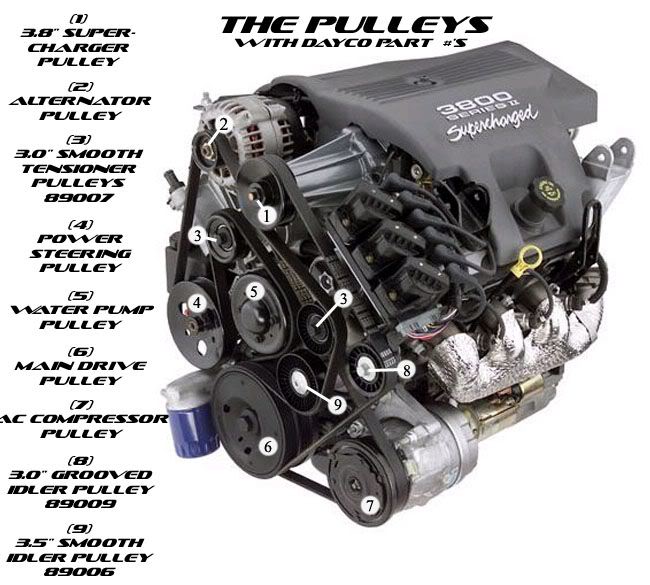

The Pulleys:

1) Accessory belt tensioner pulley (smooth, #38015, left hand thread )

2) Supercharger belt tensioner pulley (smooth, #38006, left hand thread. Note that the replacement part is a heavier metal pulley which looks nothing like the original part)

3) Supercharger idler pulley (grooved, #38009, left hand thread)

4) Supercharger idler pulley (smooth, #?????, RIGHT HAND THREAD!)

Pulleys 1, 2, and 3 are easy to replace. You'll only be able to get to #4 after removing the passenger side motor mount, the power steering pump, and the passenger side engine bracket.

Begin by de-tensioning the two tensioner pulleys (#1 and #2), and sliding the

belts off.

Use the T50 torx socket and a breaker bar. Crank the pulley bolts counter-clockwise and the pulleys will rotate downwards on their tensioner assemblies. Slip the

belts off. Crank the pulley bolts clockwise to loosen. Swap the new pulleys for the old ones, tightening the bolts in a counter-clockwise direction.

Jack up the Car and Support the Engine Once you've got the three easy pulleys replaced, it's time for the big job.

Begin by jacking up the car on the front passenger side.

Use a floor jack and your engine support to support the engine. You don't need to lift it, just get a little weight onto the jack for now.

Remove the Motor Mount

Remove the bolt indicated. It takes an 18mm and a 15 mm socket. You may need to raise or lower the jack a bit to line the bolt up right so you can pull it out.

Note that this bolt is black. Don't get it confused with the other (gray) motor mount bolt when reinstalling.

Loosen, but do not remove, 2 bolts on the inner wall of the engine bay. This takes a 15 mm wrench (not a socket, there's not enough room to use a socket)

Remove the other engine mount bolt. Note that this one is gray.

Lift out the engine mount and set it aside.

Unfasten the Power Steering Pump In order to free the engine bracket, the power steering pump must be detached from the engine.

Locate this pulley on the rear/bottom/passenger side of the engine. This is the pulley for the power steering pump. It blocks one of the studs of the engine mount bracket. Since this pulley can't be removed, the entire power steering pump will have to be. Note that the pulley has access holes in it.

You can insert a deep socket (13 mm) through these holes to get to the power steering pump mounting bolts. There's one at the top, and a second at the bottom.

Remove the power steering pump bolts.

Free the Engine Bracket

The engine bracket is held on with 3 studs. Push the power steering pump out of the way. Use a deep 15 mm socket to remove this nut. The stud may come with it. If not, use an E8 external torx socket to remove the stud.

Watch for the spacer that falls loose.

Again with the 15 mm deep socket and E8 external torx socket, remove the front top nut and stud.

The last stud is the most difficult.

It takes an 18 mm deep socket and an E10 external torx socket.

This time you need to get the nut off before you remove the stud. If you need too, use the external torx socket to hold the stud while you break the nut free. Remove the nut from the stud.

When the nut is off, unscrew the stud from the engine.

This stud is a couple inches longer than the others, and is blocked from removal by the frame rail. Tilt the engine bracket down so that the stud passes under the frame rail. If you don't have enough clearance, jack up the car (not the engine, the car) a small amount and try again.

A large spacer comes with the last stud.

Some Riv owners have elected to mod the large spacer by cutting it in half, in order to make it easier to remove the

belts the next time. With the spacer cut in half, it is not necessary to remove the engine mount, power steering pump, or the engine bracket to change the

belts. When the stud is backed out to the frame (it will strike the frame if the engine bracket isn't freed), the inner half of the spacer will drop free and it will be possible to remove the

belts through that opening.

I've decided not to cut the spacer for the following reasons:

1) it's a sturdy piece of metal and I don't think I could make a good job of it with hand tools

2) it's hard enough to remove the

belts with all three corners of the engine bracket open - I don't want to try winding them through one.

3) I don't think anyone knows how a cut spacer will perform over time. An imperfect cut might produce a stress risor which could lead to failure of the spacer. That's only speculation on my part, but I'd rather be safe than sorry.

Wind your

belts out of the engine bracket and remove them.

Replace the Last Tensioner Pulley

With the engine bracket free, it is possible - barely - to change the last tensioner pulley. Unfortunately the engine bracket can not be completely removed from the engine while the engine is still in the car. But by wriggling it into various positions and man handling it a bit the last tensioner pulley CAN be removed.

Forum member UrbsNspices reports that the engine mount bracket CAN be removed while the engine is in the car. If you've really got to have it out, try raising the engine/lowering the car. Read UrbsNspices' replies to this thread for other ideas.Begin by pushing the engine bracket as far down as you can. It should be just possible to get the T50 torx socket into the pulley bolt.

*2nd Warning* Remember, THIS pulley bolt is right hand threaded, like a NORMAL bolt. Right to tight, left to loosen! Break the bolt loose, and start backing it out. Back it out as far as you can - it will hit the engine bracket. Remember those two bolts, on the side of the engine bay, that clamped down the motor mount? Turn those in as far as they will go. Now pull the engine bracket up and away from the pulley bolt. You will have to use your fingers to back the pulley bolt out the rest of the way. Remove the old pulley.

Congratulations! Disassembly is complete! You are now ready to start putting everything back together again!!