Some information on brake pad compounds from Pegasus Racing and VWVortex.com, Racing Brake, and other sources. Puts into perspective the differences between pads made for racing vs. street vs. OEM:

OEM:

Examples: Mintex Redbox, Hawk Ceramic

Friction coefficient = 0.30-0.40

Temp before fade: 600-700°F

Duty: street use only

___________________________________________

Hawk:

HPS (F): High Performance Street. This compound will outperform OEM pads without sacrificing street manners. Stops 10% shorter than OE pads. A good choice for Solo II; also recommended for amateur to intermediate drag racing. Effective from dead cold. This versatile compound has proven to be the ultimate dual purpose street and strip material available on the market today. Recommended for amateur to intermediate forms of drag racing. Can also be used in most light duty Dirt applications where low temperature cold effectiveness is required. An excellent street pad.

Operational temperature range is 100-800 degrees F.

Friction coefficient = 0.41-0.55 (EBC pads have higher cF, Greenstuff has poorer performance on heavier cars)

Temp before fade: 700-900°F

Duty: light auto-cross and performance street use

Comparable pads: EBC Greenstuff (cF = .46 -.55 / fade: 1000ºF), EBC Redstuff (cF = .30 -.50 / fade: 1380ºF), Porterfield R4-S, Axxis Ultimate (cF = 0.46 / fade: 1000ºF)

HP Plus (N): This unique compound can take the heat at the track and get you home safely. Designed for the serious street and Autocross racer. Due to the dramatic friction level produced by this product, rotor wear, noise, dust and pad life may be affected when used for city driving. Designed as an autocross (Solo II) and track day (Solo I) compound. Very wide temperature range makes it suitable for all forms of autocross, yet still streetable. Expect an increase in dust, noise, and rotor wear.

Temperature Range: 100-800° F, for short periods of time, up to 900 degrees F.

Friction coefficient = 0.46-0.55

Temp before fade: 900-1300°F

Duty: light track days, auto-cross, and performance street use

Comparable pads: EBC Yellowstuff (cF = .50), Ferodo DS-2500, Ferodo DS-2000, Carbotech Bobcat, Carbotech Panther Plus, Mintex 1155, Carbotech AX6 & XP10, Pagid RS4-2-1 & RS4-2

DR-97 (J): Excellent static and dynamic coefficient of friction. Smooth linear torque. Low pad and rotor wear. Brake pads specifically designed for use in drag racing applications.

Temperature Range: 100 - 900º F.

Applications: Drag Racing

Black (M): Medium torque compound with high initial bite, for grass roots racing. This material was designed to be a good, all purpose low cost racing pad. Recommended for Dirt Circle Track, Dune Buggy and light duty Road Racing applications. Requires gentle initial application of the brake pedal to avoid locking. Recommended for very light sedans, small formula cars, and sports racers.

Temperature Range: 100-900° F.

Friction coefficient = 0.50-0.68 (depends on specific race application)

Temp before fade: 1300°F+ (depends on specific race application)

Duty: track use only

Comparable pads: Ferodo DS-3000, Porterfield R4, EBC Yellowstuff (cF = .50)

Blue 9012 (E): Medium/High torque brake compound with medium initial bite. A reliable performer with a wide temperature range. Low pad and rotor wear rate with good brake modulation characteristics. #1 pad material for SCCA. Recommended for Production, IT, F2000, Formula Ford, S2000, CSR, and DSR. Recommended for Road Racing and Rally applications where low to mid temperature effectiveness is critical. Also known as "Blue 9012". Temperature Range: 250-1000° F.

Friction coefficient = 0.50-0.75 (depends on specific race application)

Temp before fade: 1300°F+ (depends on specific race application)

Duty: track use only

Comparable pads: Ferodo DS-3000, EBC Yellowstuff (cF = .50), EBC Bluestuff (cF = .55 -.75), Pagid RS19/RS29, Porterfield R4

MT-4 (L): Medium/High torque and temperature compound with Medium/High initial bite. Brake pads designed for circle track cars under 2800 lbs without high deceleration rates.

Temperature Range: 400-1200º F

Duty: Pavement Circle Track under 2800 lbs.

HT10 (S): Very high torque with a smooth initial bite. Good rotor and pad life. Excellent modulation with good release characteristics. Recommended in NASCAR, Trans-Am, and all forms of road racing. Works well as a rear pad with HT14 in front. Recommended for sedans, sports racers, and formula cars with downforce, including GT, Formula Atlantic, F2000, F3000, S2000, CSR, and DSR.

Temperature Range: 300-1300° F.

Comparable pads: EBC Bluestuff (cF = .55 -.75), Pagid RS19/RS29

HT14 (V): Extremely high torque with aggressive initial bite - designed for cars with very high deceleration rates and downforce, and lots of grip. Excellent release and modulation characteristics. Recommended in Trans-Am, GT1, CART, Formula Atlantic, F2000, F3000, and Prototypes.

Temperature Range: 300-1400° F.

Newer "Dynamic Torque Control" series from Hawk. I've heard this line will eventually replace HP+ and a portion of their current line:

DTC-05 (H): Developed specifically to meet the demands of lower torque Dirt Track Racing. This friction formulation provides very controllable, higher temperature performance as compared to stock pads.

Temperature Range: 100-900F.

DTC-15 (): Developed specifically to meet the demands of Dirt Circle Track applications. DTC-15 brake pads are a medium torque compound (less torque than DTC-30, more than DTC-5) with superior release characteristics and excellent cold effectiveness.

DTC-30 (W): Brake pads designed Specifically for Dirt Circle Track applications. Uniquely controllable torque with smooth consistent feel and bite. Superior Release and torque control characteristics.

Temperature Range: 100F-1200F.

DTC-60 (W):High torque with less initial bite than DTC 70. Superior release and torque control characteristics. Brake pads designed for cars with high deceleration rates with or without down force. Recommended for use with DTC-70 when split friction between front and rear axle is desired.

Temperature Range: 400-1600° F.

DTC-70 (U): Extremely high torque with very high initial bite. Designed to be the most controllable racing brake pad available. Intended for heavier sedans and formula cars with downforce. Available for a limited selection of racing calipers. Recommended for Trans-Am, GT1, CART, Formula Atlantic, F3000, and Prototypes.

Temperature Range: 400-1600° F.

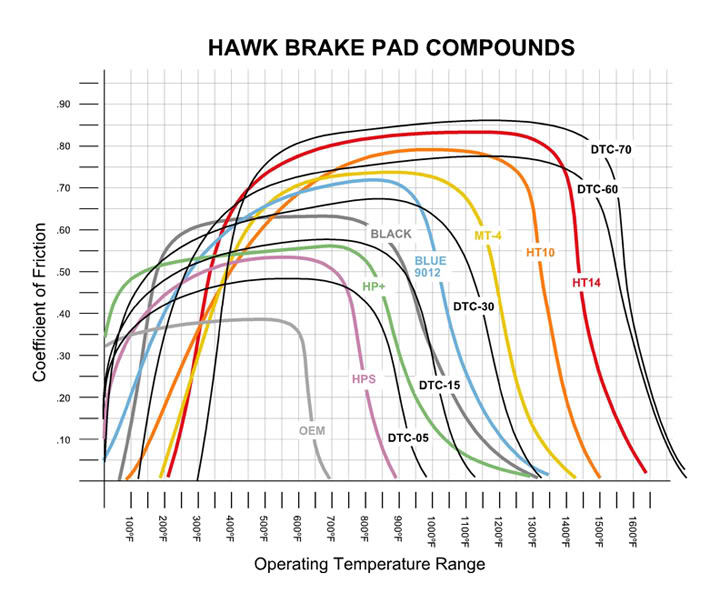

Here's a graph I made up to show some hypothetical performance curves you might expect from various Hawk pad compounds, and typical OEM (these are only guesses based on the above specs and descriptions. I haven't used or measured every one of these pads):

__________________________________________________

Performance Friction:

Z Compound: is the high-performance street compound. The Z Compound is race worthy in many applications while still suitable for everyday street use. The "CMS", "S", and "69" compounds are older, more mild street compounds.

80 Compound: was the first Carbon Metallic race material from Performance Friction. A favorite for many applications where pedal modulation is difficult, and brake balance or chassis set-up requires a more forgiving pad. Lower torque than the 83 Compound.

83 Compound: is a super high torque compound that requires finesse. The torque curve rises with heat to handle the most extreme applications. Gradually being replaced by the 01 and 03 Compounds in most applications.

90 Compound: was developed at the same time as 93 and is very similar with lower torque output. Used by several race driving schools including Bob Bondurant, Derek Daly, and Jim Russell because of its forgiving nature and long life. Gradually being replaced by the 97 Compound in most applications.

93 Compound: was developed after the 83 compound, with higher initial bite and better release characteristics for improved trail braking into corners and easier modulation at threshold braking. It is also kinder to the discs, polishing discs smooth even under severe conditions. Pad life is also very long. Requires finesse to prevent over-slowing the car. Gradually being replaced by the 01 and 03 Compounds in most applications.

97 Compound: has a very flat torque curve with less overall torque than the 01 Compound. The 97 Compound was formulated with excellent modulation and release as the primary objectives. Extremely easy on discs and very long wearing. Lowest friction of any PFC compound. Recommended for applications where wear and modulation are more important than ultimate torque.

01 Compound: has a very high, very flat torque curve for good initial bite, excellent pedal modulation, and a fast, smooth release. Torque rises very little with temperature, which makes these pads very predictable. Easy on rotors and long-wearing. All-purpose pad for a variety of racing applications.

03 Compound: has higher initial bite and higher overall torque than the 01 Compound. Torque rises slightly with temperature to handle severe braking conditions. Excellent modulation and release characteristics. Recommended for high grip, high downforce applications.

________________________________________

Pagid Race Pads:

RS-7 BLACK: (Carbon-based) A material developed for use on rear axle of front wheel drive circuit racing cars with low rear axle weight. Lower friction levels help to reduce rear wheel lock.

Cold: 212ºF-572ºF / Working: 572-932ºF / Max: 1,022ºF / cF = 0.32 0.33 0.35 0.37

RS4-2-1 BLACK: (Carbon-based) A very stable material with low disc wear. It has a wide operating range with good low temperature performance and low brake noise. Fitted as original equipment on many high performance road vehicles, this is the best all round pad for road use.

Cold: 212ºF-572ºF / Working: 572-932ºF / Max: 1,022ºF / cF = 0.36 0.38 0.42 0.45

RS4-2 BLUE: (Carbon-based) The most popular material (known as 'Pagid Blue'), RS4-2 gives a good low temperature response. It is very stable with superior modulation and feel. RS4-2 has a medium co-efficient of friction with good pad and disc life. Suitable for many applications especially gravel rally and wet tarmac, where control is needed.

Cold: 212ºF-572ºF / Working: 662-1,112ºF / Max: 1,202ºF / cF = 0.4 0.42 0.46 0.49

RS4-4 ORANGE: (Carbon-based) This material has a high friction level especially at high temperature. It is better for high temperature applications than RS4-2 and has a very stable torque pattern. Suitable for rear axle use on Touring Car applications and very popular in Porsche racing.

Cold: 212ºF-572ºF / Working: 662-1,202ºF / Max: 1,292ºF / cF = 0.39 0.4 0.48 0.53

RS-19 YELLOW: (Ceramic-based) This material provides very good performance at all temperatures with immediate brake response. Very stable pad on ceramic base, with excellent fade resistance and low disc wear. Suitable for endurance racing or applications where exceptional life is required.

Cold: 212ºF-572ºF / Working: 752-1,292ºF / Max: 1,382ºF / cF = 0.4 0.43 0.47 0.49

RS-14 BLACK: (Ceramic-based) A high friction, high temperature material with enviable pad life at this level of friction. Very kind to discs, easily modulated and resistant to wheel lock in extreme use. Suitable for Touring Car, WRC, GT and other forms of medium weight single seater race cars that have good levels of grip.

Cold: 212ºF-572ºF / Working: 752-1,292ºF / Max: 1,472ºF / cF = 0.44 0.47 0.49 0.54

RS-15 GREY: (Ceramic-based) The newest material, a development of RS-14 which combines a 20 percent higher friction level with an improved initial bite. RS-15 has a very good life and exceptional release characteristics. It is also very easily bedded in comparison to it's competitors. Suitable for Touring Car, GT and other applications requiring very high levels of friction and high temperature stability.

Cold: 212ºF-572ºF / Working: 752-1,472ºF / Max: 1,652ºF / cF = 0.50 0.54 0.57 0.62

______________________________

EBC:

Redstuff: Low dust EBC Redstuff is a superb pad for fast street use and targets High HP imports, muscle cars and prestige European cars. EBC Redstuff Ceramic pads REDUCE DUST emitted by OEM pads by approx 80%. Redstuff pads also reduce rotor wear so that rotors and pads last longer whilst delivering great brake performance. For optimum lifetime in track use, EBC still recommend drivers to upgrade to their Yellowstuff or even the new Bluestuff range but if Fast street is what you need, EBC Redstuff Ceramic is the pad to choose.

Yellowstuff: compound is essentially a race pad but with a BIG difference in that it works from cold and can be safely used on the highway. If you want the ultimate in high friction braking, this is the pad to choose. Brakes feel superb from first touch of the pedal and stay effective up to race temperatures. EBC Yellowstuff is designed for faster imports and muscle cars where maximum stopping is the prime requirement and for short duration track use. Its dust rating is similar to OEM parts. All pads come with edge chamfers, center line slots, noise reduction shims and OEM hardware as needed. All EBC pads feature the EBC Brake-In surface coating which helps pads seat quickly after install.

Bluestuff: NDX Formula brake pads are the ultimate high friction race pad, even superb as a brake upgrade for street driving. Due to the high initial or cold bite, the Bluestuff pads feel great from first pedal right up to race temperatures. The friction level of these pads is over 0.6µ which is huge in friction rating terms. Built with interlayer technology and multiple spigot holes for superb pad retention, Bluestuff will impress all sportscar and muscle car drivers in track use and even on the drive to and from the track. EBC Bluestuff uses a revolutionary man made fiber and does NOT employ cheap steel fibers that cause hot sparks and damage caliper seals and wheel rims alike. Bluestuff is also easier on rotors than most race pads. Designed for mid to heavy car weights and horsepowers, for lighter vehicles EBC Yellowstuff is your race and fast street choice option.

_____________________________________

Racing Brake:

ET Series Characteristics:

* Excellent Modulation

* Consistent friction and torque output

* Run from ambient temperature (even in cold winter morning) - ET500 & ET700

* Extended life if they are used under the temperature guide

* Affordable pricing

ET300: * Upgrading stock pads to street performance

* Very low dust, no squeaking

ET500: * Great for the street, good for occasional light track events

* Guaranteed no-fade up to 1000°F / 537°C

* Very low dust, none to minimal squeaking

ET700: * HPDE and entry level racing, also good on the street

* Excellent heat characteristics

* Guaranteed no-fade up to 1200°F / 648°C

* Occasional low squeaking on street driving - RB brake shims may be added as needed

ET800: * Excellent heat characteristics and modulation

* High temperature, guaranteed no-fade up to 1400°F / 760°C

* Lower torque and deceleration rate than ET900 series

ET900: * For motorsports racing only (not recommended for street driving)

* Excellent heat characteristics and modulation

* High temperature, guarantee no-fade up to 1600°F / 871°C

* High torque and high deceleration rate

Links: http://www.pegasusautoracing.com/document.asp?DocID=TECH00062

http://forums.vwvortex.comhttp://www.perfectbrakes.com/products.asp?cat=1624

http://www.racingbrake.com/v/main/rb_pads.asp