| | Porting & Polishing Gen III Blower |  |

|

+18matt270avian charlieRobinson Snowdog robotennis61 DOHCZ34 Supercharged TonySmooth89 Jason EASHER palermocorey90 Karma turtleman oldsman105 Mr.Riviera dreww T Riley Rickw AA 22 posters |

|

| Author | Message |

|---|

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 9:44 am Tue Apr 21, 2015 9:44 am | |

| - Sir Psycho Sexy wrote:

- Matt, gen Vs are all over online for less than $200.

As for the aluminum plate+Quicksteel, unless you are using an intercooler, DO NOT DO IT. For anyone else reading, now and in the future. Being as I've made quite a number of them... Logistics of making a pocket in the blower and fabricating an insert plate aside: As long as the plate is physically larger than the square hole in the LIM and its edges end up flush with the bottom of the blower there is no issue. Even without an inter-cooler. But there are a few of "ifs" in that statement. _________________  | |

|

| |

matt270avian

Expert

Name : Matt

Age : 28

Location : Frederick, MD

Joined : 2012-01-15

Post Count : 2681

Merit : 54

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 9:58 am Tue Apr 21, 2015 9:58 am | |

| My logic behind it is actually pretty simple. A lot of people just use JB/quiksteel to fill the silencer holes. It works well, but people have had it dislodge and go into the engine. If you cover the entire bottom of the blower with quiksteel, and then press/clamp the aluminum sheet onto the bottom there is no way it's ever coming off.

Basically this, just not as sloppy:

http://www.grandprixforums.net/threads/65065-Safely-Filling-Silencer-Holes-on-ported-Eaton-M90-Gen-III-Supercharger-with-(PICS)?highlight=port | |

|

| |

charlieRobinson

Expert

Name : Charlie

Age : 39

Location : Knoxville, TN

Joined : 2011-05-17

Post Count : 3924

Merit : 31

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 10:02 am Tue Apr 21, 2015 10:02 am | |

| Notice how the rotors on the blower you linked above have no coating and appear to be scraped and hacked up pretty good.  I wouldnt follow that guy. Why are you guys even trying to do this? Seems like a lot of risk for little to negative gainz. | |

|

| |

matt270avian

Expert

Name : Matt

Age : 28

Location : Frederick, MD

Joined : 2012-01-15

Post Count : 2681

Merit : 54

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 10:06 am Tue Apr 21, 2015 10:06 am | |

| - charlieRobinson wrote:

- Notice how the rotors on the blower you linked above have no coating and appear to be scraped and hacked up pretty good.

He stripped the teflon on them. Said something about it flaking off so he just stripped them completely. I plan on leaving the coating, or getting them recoated if need be. | |

|

| |

Sir Psycho Sexy

Junkie

Name : Tyler

Age : 30

Location : Temperance, Michigan

Joined : 2012-06-22

Post Count : 948

Merit : 20

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 12:03 pm Tue Apr 21, 2015 12:03 pm | |

| - Karma wrote:

- Sir Psycho Sexy wrote:

- Matt, gen Vs are all over online for less than $200.

As for the aluminum plate+Quicksteel, unless you are using an intercooler, DO NOT DO IT.

For anyone else reading, now and in the future. Being as I've made quite a number of them... Logistics of making a pocket in the blower and fabricating an insert plate aside: As long as the plate is physically larger than the square hole in the LIM and its edges end up flush with the bottom of the blower there is no issue. Even without an inter-cooler. But there are a few of "ifs" in that statement. Karma, what you do is superb. I'm talking about anyone trying to do a hackjob at home. Don't just glue in a piece of 1/32 sheet aluminum and think you're going to have a good time... I know from experience that no matter how well you prep things and follow directions, the quickweld stuff can let go. The thin metal plate can get sucked into the blower or cylinders or whatever, and you'll have a real mess. I think it was a fad for a while to strip the coating off the rotors so the blower would bleed boost and be less efficient, so you could use a smaller pulley. I don't think there's any logic to it. It's just you can say, "bro my pulley is smaller that yours bro." | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 12:28 pm Tue Apr 21, 2015 12:28 pm | |

| - Sir Psycho Sexy wrote:

- Karma wrote:

- Sir Psycho Sexy wrote:

- Matt, gen Vs are all over online for less than $200.

As for the aluminum plate+Quicksteel, unless you are using an intercooler, DO NOT DO IT.

For anyone else reading, now and in the future. Being as I've made quite a number of them... Logistics of making a pocket in the blower and fabricating an insert plate aside: As long as the plate is physically larger than the square hole in the LIM and its edges end up flush with the bottom of the blower there is no issue. Even without an inter-cooler. But there are a few of "ifs" in that statement.

Karma, what you do is superb. I'm talking about anyone trying to do a hackjob at home. Don't just glue in a piece of 1/32 sheet aluminum and think you're going to have a good time...

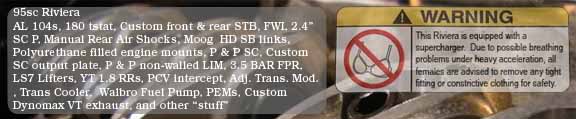

Yup.  That's why I said there were quite a few "ifs" in that statement. That blower up there is, um, something isn't it? _________________  | |

|

| |

matt270avian

Expert

Name : Matt

Age : 28

Location : Frederick, MD

Joined : 2012-01-15

Post Count : 2681

Merit : 54

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 2:12 pm Tue Apr 21, 2015 2:12 pm | |

| Well, do you guys think I should weld the silencers shut instead? I didn't want to do that for fear of warping anything..... | |

|

| |

Karma

Aficionado

Name : Andrew

Age : 40

Location : Ontario, Canada

Joined : 2008-01-14

Post Count : 1949

Merit : 123

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 2:30 pm Tue Apr 21, 2015 2:30 pm | |

| Welding would kind of be a coin toss. You know there are a few who have done it and reported success. The big concern is of course distorting the rotor bore. But, if it was tig'ed, and carefully done, would be a relatively easy and cheap way to do it, if someone had their heart set on plugging them. There is a fine line in getting enough heat in it to lay a nice bead, but not so much to trigger a distortion. I've heard various strategies, such as doing little bits quick and alternating between the two sides to keep heat down, or heating the entire thing up in an oven and then quickly tig'ing it.(In theory the oven heat keeps a narrower range of temps across the casting.) It would all be up to whatever the welder had experience in and wanted to try. The other wrinkle is that sand cast aluminum such as our blowers are very very slightly porous, and suck up oil during their life. That can make welding a bit of an adventure as the heat boils out the crap and makes poor welds. Being how generally cheap and available gen3 blower cases are nowadays, it could be an avenue to try. Find the oldest most knowledgeable guy you can with experience in tig'ing cast aluminum and see if they will give it a try. Just get it welded and tested out before taking the time porting the rest just in case it doesn't work out. _________________  | |

|

| |

matt270avian

Expert

Name : Matt

Age : 28

Location : Frederick, MD

Joined : 2012-01-15

Post Count : 2681

Merit : 54

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  Tue Apr 21, 2015 2:39 pm Tue Apr 21, 2015 2:39 pm | |

| I might even just leave it if it's going to be that much of a headache.... I've got it pretty smooth and clean now, don't want to risk ruining it. | |

|

| |

Sponsored content

|  Subject: Re: Porting & Polishing Gen III Blower Subject: Re: Porting & Polishing Gen III Blower  | |

| |

|

| |

| | Porting & Polishing Gen III Blower |  |

|